- Critical joint consultation, Inspection & Monitoring – Supply of competence personnel, Technical support, and advice

- Controlled bolting works (MTW, HTW, HBT) – Hot bolting/Odd Bolting

- On-Site Machining – Cold cutting and bevel

- Flange resurface, repair – weld build up & replace

- Thorough inspection and supervision by competent personnel at 3 major stages (recommended for best result)

Stage 1: Preparation-material selection & purchasing, joint identification (line walk-visual inspection)

Stage 2: Installation – witness and inspection on site during job execution (Procedure & method of tightening-provide optimum torque & tensioning value)

Stage 3: Handover – final report and database record-traceability ensured & easily accessible

- Flange Management software (ATW – INTEGRITY PRO)-comprehensive database system

- Leak Testing (Hydrostatic, N2, Helium)

- Leak sealing (On-line using clamp / Pipe Freezing-temporary pipe isolation by creating freeze plug)

- Real-time condition-based monitoring (Live monitoring on critical joint)

- Bolt Load verification (UT Tools)

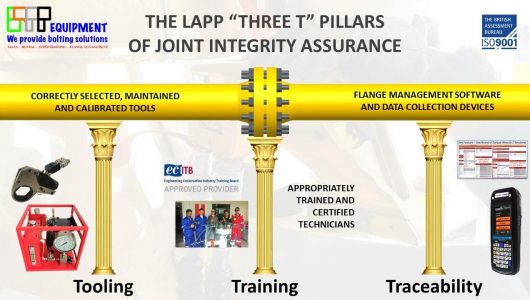

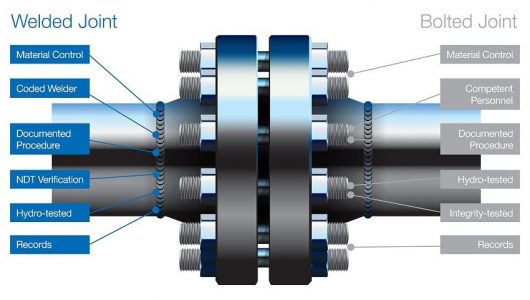

Typical elements (as per EI Guidelines) for Joint Integrity assurance are as follows:

- understanding of the operating environment

- continues with design

- selection of the flange components

- setting of assembly specifications

- establishment of best procedures

- appointment of competent personnel

- quality assurance traceability through complete documentation (using sophisticated and systematic software for database)

- finishes with meeting the goal of leak prevention